How to Choose the Best Spin Coating Machine — No Guesswork

An Informational Guide for Indian Labs, R&D Teams, and Scientists

Why The Spin Coater Selection is More Important Than You Think

A spin coater isn’t just another lab tool. It directly affects:

- Film uniformity and thickness control

- Data repeatability

- Your ability to publish or prototype faster

But with dozens of options, confusing specs, and inconsistent advice, making the right choice can feel like flying blind.

What This Page Will Help You Understand

- ✅ The real factors that matter when choosing a spin coater

- ✅ Why most labs waste money on overkill or underspecified machines

- ✅ How to compare vendors in a clear, scientific way

- ✅ What questions to ask (yourself and suppliers) before deciding

- ✅ Where to get objective help — if you want it

The 5 Critical Factors to Evaluate in Any Spin Coating Machine

- Substrate Size & Holding Mechanism: Make sure the vacuum chuck or holder is compatible with your actual sample sizes. Too large = wasted RPM efficiency. Too small = instability.

- Speed & Acceleration Ranges: You rarely need 12,000 RPM. What you need is stable, accurate speed across the range you’ll actually use (e.g., 500–5000 RPM).

- Material Compatibility: Corrosive solvents? Moisture-sensitive films? Look at chamber material, coating, and dispensing setup.

- Repeatability & Programming: Automation and programmability reduce human error. But also: how easy is it to save, retrieve, and modify recipes?

- Service & Support in India: Even the best equipment fails if the team behind it isn’t responsive. Ask about local repair timelines, warranty clarity, and post-sale access.

5 Common Pitfalls to Avoid

| Pitfall | Why It Hurts |

|---|---|

| Buying based on RPM alone | Many vendors inflate this spec — stability matters more than peak speed |

| Ignoring future scalability | You may need vacuum-less or hybrid holding later — upgrade paths matter |

| Choosing a vendor without checking user support | Post-sale service often determines long-term success |

| Not comparing quotes side-by-side | Hidden costs (shipping, training, warranty exclusions) add up |

| Rushing due to grant pressure | Poor fit machines often create rework and loss of credibility |

Before You Buy: Questions to Ask Every Supplier

- What’s the accuracy tolerance of your RPM at 2000–3000 RPM?

- Can I see actual test data or videos with substrates similar to mine?

- How long does it take to deliver to [your city]?

- What’s included in the warranty — and what’s not?

- Can you share reference labs who’ve used this model?

Bonus Free Tools for Smarter Sourcing

These free resources are designed to make you feel confident, not confused:

- 🔍 Spin Coater Pre-Purchase Checklist

- 🔬 Spin Coating Process Optimization Guide

- 🧰 Basic Maintenance Toolkit

- 📅 Free Expert Call (Optional — not sales)

You can download all of these here: 📥 Get the Spin Coater Sourcing Toolkit

Free Sourcing Call

Completely Confidential – Speak directly with product experts. We’ll email a pre-purchase checklist and bonus toolkit for your reference.

About Scientific EQ

We’re not a manufacturer or a supplier. We may earn from affiliate commissions if you buy products linked from our website. Scientific EQ is a neutral team that helps researchers, procurement heads, and PhDs:

- Compare quotes fairly

- Avoid regretful purchases

- Speed up the sourcing process

- Focus on research, not chasing suppliers

We help you focus on research, not chasing suppliers. Because in research, what you don’t buy matters just as much as what you do.

We’re here to reduce confusion, not create it.

Important Disclaimer

This site offers general information and best practices for spin coating applications. It is not intended as a substitute for professional training, specific equipment operation manuals, or a comprehensive understanding of the materials involved. Users bear sole responsibility for ensuring safe operation, appropriate material selection, and adherence to all relevant safety and environmental regulations.

Should you identify any discrepancies or have questions regarding the content of this guide, please contact us promptly at scientificeq@aidasinc.com. We are committed to rectifying any inaccuracies and will gladly acknowledge contributing sources.

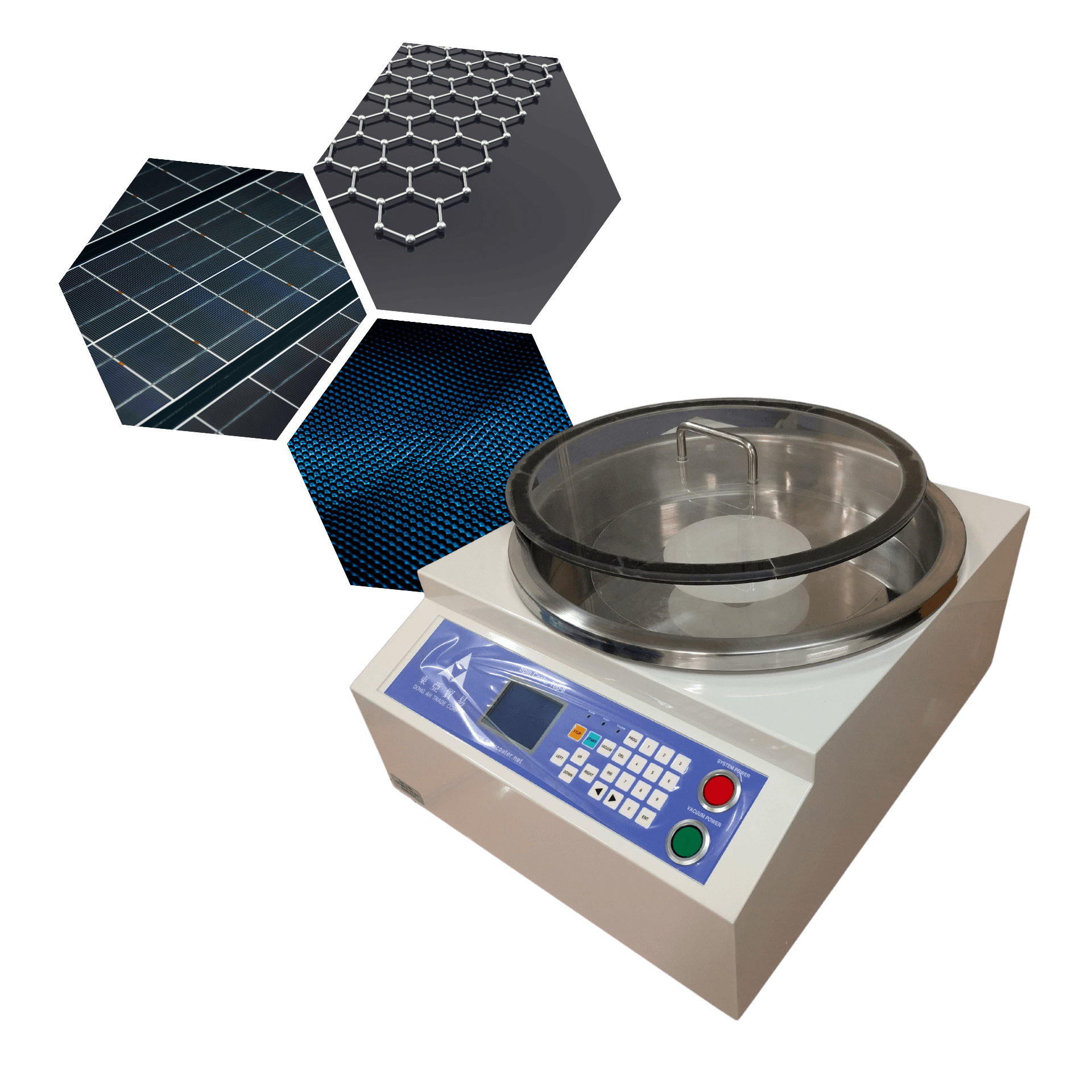

Bringing in that perfect spin coating machine for your research

Enhance your lab’s capabilities with the right spin coater from the numerous options available in the market. See ranked below the list of 25+ most important features users reported while ranking a Spin Coater Machine.

| Feature | Description |

|---|---|

| Speed (100 – 12000 RPM) | High-speed range for versatility in different applications; critical for broad usability. |

| Speed Accuracy (± 1%) | Ensures consistent and reliable results, important in research and production. |

| Acceleration (Up to 8000 RPM/s) | High acceleration reduces process times and boosts throughput. |

| User Interface (7-inch touch display) | Intuitive interface enhances user experience and operational efficiency. |

| Programmable Parameters | Customization of spin speed, duration, and acceleration for repeatable, tailored processes. |

| Safety Feature (Lid Interlock) | Prevents operation with open cover; enhances user safety. |

| Graph Display (LIVE RPM vs TIME) | Real-time monitoring enables precise control and quick troubleshooting. |

| Storage Capacity (Up to 32 GB) | Ample space for saving programs and process data. |

| Substrate Holding Mechanism | Hybrid vacuum and vacuum-less options support a wide range of substrates. |

| Housing Material | Corrosion-free, powder-coated sheet metal ensures durability and chemical resistance. |

| PC Connectivity | Allows integration with external systems for extended control and data analysis. |

| Installation Support | Professional support ensures proper setup and functionality. |

| Warranty (12 Months) | Provides assurance of product quality and support. |

| Memory Type (Non-Volatile) | Retains settings and programs even after power off. |

| Manuals Provided | Includes manuals for the spin coater and accessories, plus a complete spare part list. |

| Chucks (Universal Vacuum Chuck) | Supports various substrate sizes and types. |

| Nitrogen Purging | Lid includes pneumatic connection for nitrogen purging to prevent oxidation. |

| Working Chamber Material | Natural PP with transparent lid offers chemical resistance and process visibility. |

| Liquid Dispensing | Center hole in lid allows easy, integrated liquid dispensing. |

| Enhanced Vibration Damping | Minimizes vibration to improve coating uniformity and film quality. |

| Power Requirement | 220V AC/50Hz; includes DC adapter for standard lab integration. |

| Drainpipe (Side of the chamber) | Efficient drainage for ease of cleaning and maintenance. |

| Additional Vacuum Connections | Includes 10mm PU hose (2m length) for added flexibility. |

| Touch Screen | Simplifies data entry and programming. |

| High Stability of Run | Minimizes oscillation from set RPM, improving process reliability. |

| Natural PP Sample Holder/Chuck | Chemically resistant and durable for secure sample placement. |

This ranking prioritizes features that directly impact the precision, versatility, safety, and ease of use of the spin coating process.