What if You Didn’t Have to Struggle Anymore? How to End the Cycle of Frustrating Spin Coater Choices in India.

For Indian labs, R&D teams, and scientists, achieving precise and uniform thin films is paramount as we discussed on our main guide. So a spin coater is far more than just a lab tool for you – it directly impacts your film uniformity, data repeatability, and speed to publication or prototyping. While the core principles of choosing the best spin coater remain universal, understanding the specifics of spin coating machine manufacturers in India is crucial for your local procurement goals.

In India’s vibrant research ecosystem and the “Make in India” initiative have fostered a growing landscape of indigenous spin coater manufacturers. This article serves as a deeper dive, helping you navigate this local market and ensure you invest in a machine that truly meets your advanced thin-film deposition needs.

The Power of Precision: Understanding Spin Coater Features in Detail

While the general principles of spin coating are widely understood, the nuances of machine selection often remain overlooked as it’s not just about getting a thin film; it’s about consistent thin films, reproducible results, and ultimately, accelerating your scientific discovery.

So when evaluating spin coating machines, particularly from local manufacturers, it’s essential you look beyond marketing claims and focus on the technical specifications that drive performance. Building on the “5 Critical Factors” outlined on our main page, here’s a detailed breakdown of what the industry considers most important:

- Shocking Perspective 1: The Hidden Cost of “Good Enough” as many institutions, especially those with budget constraints, opt for a “good enough” spin coater. What often goes uncalculated is the long-term cost of inconsistency: wasted materials due to non-uniform films, lost research hours re-doing experiments, delayed publications, and missed opportunities for innovation. An underspecified machine can be a silent killer of productivity and a drain on resources far beyond its initial purchase price, thus you investing wisely upfront in a high-quality spin coater from reputable Indian manufacturers can save your team from years of frustration and millions in indirect losses.

- Unthought-of Narrative: The Strategic Advantage of Local Manufacturing goes beyond cost, opting for spin coating machine manufacturers in India offers a strategic advantage. It’s not just about patriotism; it’s about unparalleled local support, faster service timelines, easier access to spare parts, and the potential for customized solutions precisely tailored to your unique, often niche, research needs. This level of responsiveness is rarely matched by international suppliers, especially when dealing with unforeseen technical challenges.

Top Features Users Report While Ranking a Spin Coater Machine:

| Feature | Description |

|---|---|

| Speed (100 – 12000 RPM) & Accuracy (± 1%) | Ensures versatile film thickness control and high repeatability. Look for machines with stable performance at various RPMs. |

| Acceleration (Up to 8000 RPM/s) | High and programmable acceleration minimizes solvent evaporation, improving film uniformity, especially for fast-drying materials. |

| Programmable Parameters & Storage | Multi-step control for speed, duration, and acceleration/deceleration, plus memory (e.g., 32 GB) for recipe storage and reproducibility. |

| User Interface (e.g., 7-inch touch display) & Live Data | Touchscreen with real-time RPM vs. Time graph for precise control, immediate troubleshooting, and user-friendly operation. |

| Storage Capacity (Up to 32 GB) | Non-volatile memory allows saving numerous programs and data, preserved even after power-off. |

| Substrate Holding Mechanism (Hybrid Vacuum & Vacuum-Less Options) | Supports diverse substrate types and fragile materials with flexible chuck options. |

| Housing Material (Corrosion-Free, Powder-Coated Sheet Metal) | Resistant to corrosive solvents, ensuring durability and long equipment life. |

| Working Chamber Material (Natural PP with Transparent Lid) | Chemically resistant with a clear lid for visibility during operation. |

| Safety Features (Lid Interlock) | Prevents operation when the lid is open, protecting users from hazards. |

| PC Connectivity | Enables integration with external systems for advanced control, analysis, and remote monitoring. |

| Installation Support | Ensures correct setup and optimal performance from the start. |

| Warranty (12 Months) | Provides assurance of product quality and post-sale support. |

| Nitrogen Purging (Pneumatic Connection in Lid) | Protects oxygen/moisture-sensitive materials during coating by preventing oxidation. |

| Liquid Dispensing (Center Hole in Lid) | Allows clean, integrated liquid dispensing to simplify the coating process. |

| Enhanced Vibration Damping | Reduces oscillations for improved coating uniformity and fewer defects. |

| Drainpipe (Side of the Chamber) | Facilitates easy cleaning and prevents cross-contamination. |

| Additional Vacuum Connections (10mm PU hose – 2m length) | Offers flexibility for external vacuum sources or setups. |

| Manuals Provided | Includes complete guides and spare part lists for independent operation and maintenance. |

| Natural PP Sample Holder/Chuck | Durable and resistant to chemicals, ensuring secure sample placement. |

| Power Requirement (e.g., 220V AC/50Hz; DC Adapter provided) | Compatible with standard power setups in Indian labs, with adapters included. |

Navigating the Indian Spin Coater Manufacturing Landscape

While the global market includes giants, spin coating machine manufacturers in India are increasingly stepping up to offer you competitive and innovative solutions, their strengths often include:

- Cost-Effectiveness: Often providing you a more budget-friendly entry point for high-performance equipment.

- Customization: A greater willingness to tailor specific features or chuck designs to your unique research needs.

- Localized Support: Easier and faster access for you to technical support, spare parts, and on-site servicing.

- Understanding Local Context: A better grasp of procurement processes, power fluctuations, and environmental considerations specific to the lab you lead.

When engaging with an Indian manufacturer, apply the “Questions to Ask Every Supplier” outlined on our main page, and supplement with specific inquiries about their manufacturing process, quality control, and long-term support infrastructure within India.

Here are some of the prominent spin coating machine manufacturers in India, shaping1 the landscape of thin film deposition:

| Apex Instruments | Mechanics Optics & Digital Instruments |

| Biostag Technologies | Milman Thin Film Systems |

| CAPITAL Lab Tech | MRC Laboratory Instruments |

| City Instruments | Navson Technologies |

| Delta Scientific | Ossila |

| Holmarc | SPS Polos |

| Hydro Pneo Vac Technologies | Raman Labs |

| Instras Scientifics | Scientific & Analytical Instruments |

| Jetspin | SCS (Specialty Coating Systems) |

| Mahendra Scientific Instruments | VB Ceramic Consultants |

Industry Snapshot: India’s Growing Demand for Precision Coating Technology

The demand for advanced coating equipment, including spin coaters, is intrinsically linked to the growth of high-tech industries in India and you have a big role to play in this fast developing scenario.

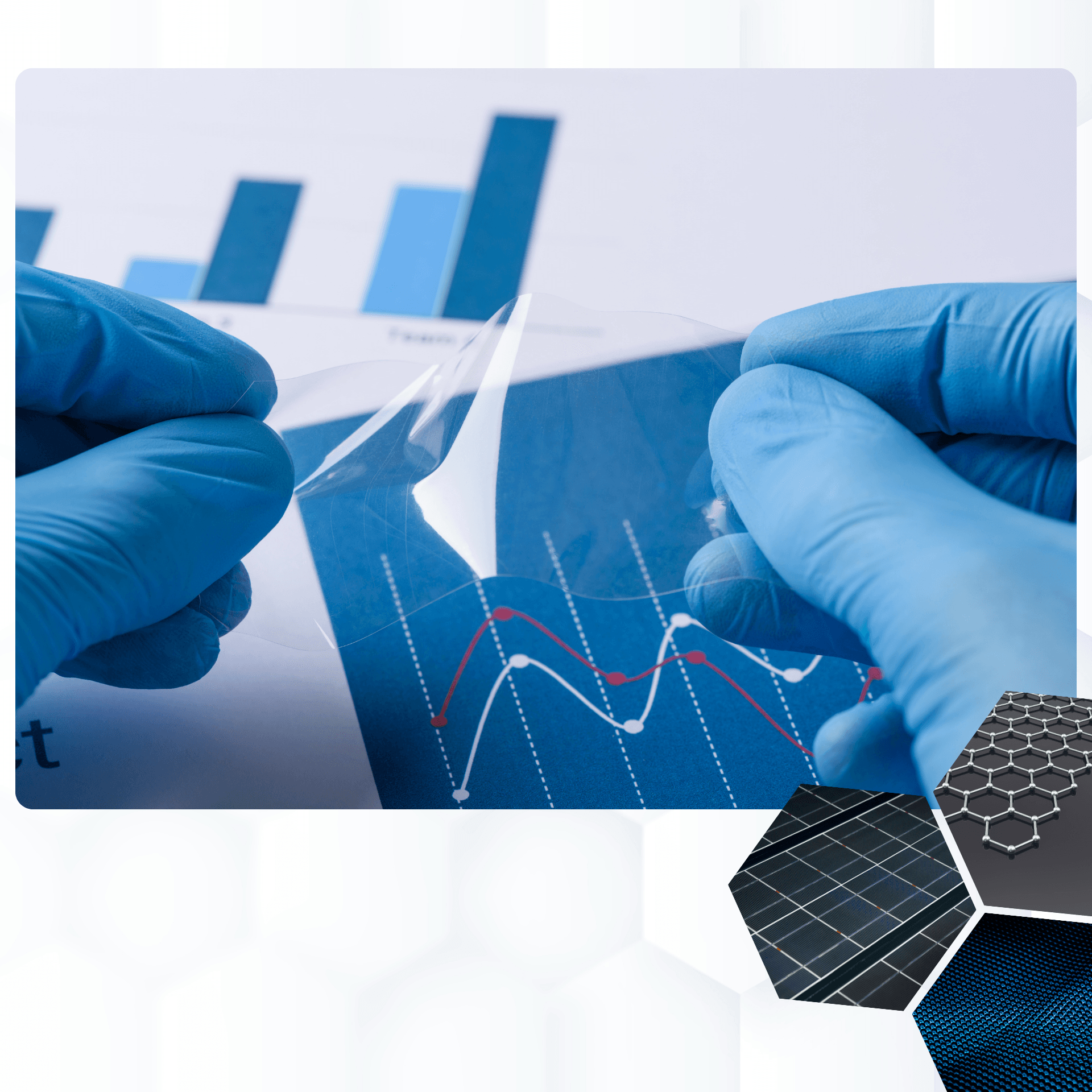

- Semiconductor Growth: India’s semiconductor consumption market is projected to reach $52 billion in 2024-25 and grow to $103.4 billion by 2030 (Source: IESA report, Business Standard). This explosive growth in mobile handsets, IT, telecommunications, and automotive sectors directly fuels the need for precise thin-film deposition tools like spin coaters for lithography and advanced packaging.

- Thin Film Coating Market: The global thin film coating market size was estimated at $37.11 billion in 2024 and is expected to reach $60.06 billion by 2034, with a CAGR of 4.93% (Source: Market Research Future). The APAC region, including India, is projected to witness substantial growth, driven by electronics and consumer goods. This indicates a sustained demand for spin coating solutions.

- Emerging Trends in Coatings: The broader surface coating industry is seeing trends like the emergence of eco-friendly coatings, smarter coatings (self-healing, anti-microbial), and a significant rise in nanotechnology applications to improve UV resistance, corrosion protection, and mechanical strength (Source: SAR Coatings, June 2025). Spin coating is a fundamental technique for developing many of these next-generation materials and functionalities, especially at the nanoscale.

Empowering Your Research with the Right Partner

Choosing a spin coating machine, and indeed, the right manufacturer, is a strategic decision for you and for any Indian lab. By understanding the critical features that truly matter and leveraging the growing capabilities of spin coating machine manufacturers in India, you can make an informed decision that enhances your lab’s capabilities, streamlines your thin-film deposition, and accelerates your path to scientific breakthroughs.

Ready to simplify your spin coater procurement?

At Scientific EQ, we provide unbiased, expert guidance to help Indian labs compare quotes fairly, avoid regretful purchases, and speed up the sourcing process. You can start with these free resources that are designed to make you feel confident, not confused:

- 🔍 Spin Coater Pre-Purchase Checklist

- 🔬 Spin Coating Process Optimization Guide

- 🧰 Basic Maintenance Toolkit

- 📅 Free Expert Call (Optional — not sales)

Free Sourcing Call + Spin Coater Sourcing Toolkit: Start Now📥

Free Sourcing Call

Completely Confidential – Speak directly with product experts. We’ll email a pre-purchase checklist and bonus toolkit for your reference.

About Scientific EQ

We’re not a manufacturer or a supplier. We may earn from affiliate commissions if you buy products linked from our website. Scientific EQ is a neutral team that helps researchers, procurement heads, and PhDs:

- Compare quotes fairly

- Avoid regretful purchases

- Speed up the sourcing process

- Focus on research, not chasing suppliers

We help you focus on research, not chasing suppliers. Because in research, what you don’t buy matters just as much as what you do.

We’re here to reduce confusion, not create it.

Important Disclaimer

This site offers general information and best practices for spin coating applications. It is not intended as a substitute for professional training, specific equipment operation manuals, or a comprehensive understanding of the materials involved. Users bear sole responsibility for ensuring safe operation, appropriate material selection, and adherence to all relevant safety and environmental regulations.

Should you identify any discrepancies or have questions regarding the content of this guide, please contact us promptly at scientificeq@aidasinc.com. We are committed to rectifying any inaccuracies and will gladly acknowledge contributing sources.